The Institute of Multimaterial Science of Tohoku University and Showa Electric announced that they have jointly developed a technology for mass production of high-quality graphene sheets.

2022-05-10 444The Institute of Multimaterial Science of Tohoku University and Showa Electric announced that they have jointly developed a technology for mass production of high-quality graphene sheets. This means that an important step has been taken in the use of graphene as a battery material and a lightweight high-strength structural material for automobiles.

Graphene is a material that is stripped from graphite as a carbon material with a thickness of one atom. In addition to being used as electronic components such as transistors, materials and structural materials of batteries have also attracted much attention. However, most of the existing manufacturing methods of graphene are very slow, and it is difficult to achieve mass production of high-quality graphene with few defects and impurities. For example, as one of the chemical stripping methods, the "oxidative stripping method" can obtain graphene flakes by oxidizing the graphite powder and stripping it in the solvent, and then reducing it, but it takes more than one day to process at a time, and there are many defects and impurities.

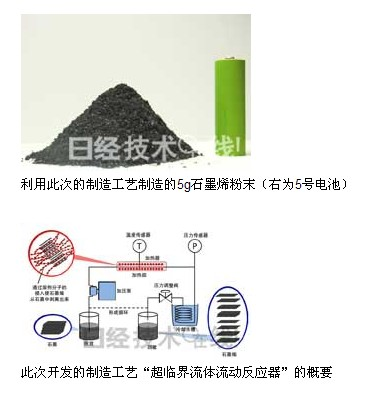

The method developed this time uses supercritical liquid of organic solvent such as ethanol to peel graphene. According to Japanese Tohoku University professor Ben Zaige, since no oxidation treatment is carried out, "there are almost no impurities such as oxygen and hydrogen". Moreover, a "flow reactor" that can continuously peel off graphene has been developed. For 5g raw materials, the time of one peeling treatment is only about 1 hour.

However, the yield of single-layer graphene after one treatment is only about 10%. In order to solve this problem, Northeastern University and Zhaohe Electrician have also developed a method to make the stripping process cycle and repeatedly treat at 400 ℃. In this way, the yield of graphene monolayer can be improved. Specifically, the harvest rate can be increased to more than 30% after 12 times of repeated treatment and more than 80% after 48 times of repeated treatment. In 48 times of repeated treatment, although the treatment capacity per hour will drop to about 100mg of raw materials, the production efficiency is still higher than that of oxidative stripping method.

In terms of the quality of graphene obtained, our professor said that "the detection of Raman spectrum D-band and G-band confirmed that the graphene obtained after 48 times of repeated treatment showed excellent quality". However, the carrier mobility was not determined. Moreover, the particle size of graphene is not disclosed. In the future, Zhaohe Electric will further verify the technology that can improve mass production efficiency for business operation.

- Previous:In order to further enhance t…

- Next:Chongqing Channel News Do …